اطلاعات پروژه

- دسته بندی: Products

- REMOTE ENGINE/GEARBOX/THRUSTER/CPP CONTROL & SAFETY SYSTEM (ZMZ-002577/002579) :

جزئیات پروژه

INTRODUCTION: Mainly offshore vessel’s owners are concentrating on the hull-refurbishing & engine/Propulsion repair; they’re neglecting to concentrate on the brain of the vessel: Remote Control & Safety system renovation/ upgrade. Our safety/remote control system for the offshore vessels ( like the Azimuth Stern Drive) basis on the marine-approved type Programmable Logic Controller (PLC), integrates various […]

ادامه جزئیات پروژه

INTRODUCTION: Mainly offshore vessel’s owners are concentrating on the hull-refurbishing & engine/Propulsion repair; they’re neglecting to concentrate on the brain of the vessel: Remote Control & Safety system renovation/ upgrade.

Our safety/remote control system for the offshore vessels ( like the Azimuth Stern Drive) basis on the marine-approved type Programmable Logic Controller (PLC), integrates various control and safety functions, allowing operators to manage the ship’s propulsion systems from the several remote stations (combining the CPP & RPM control).

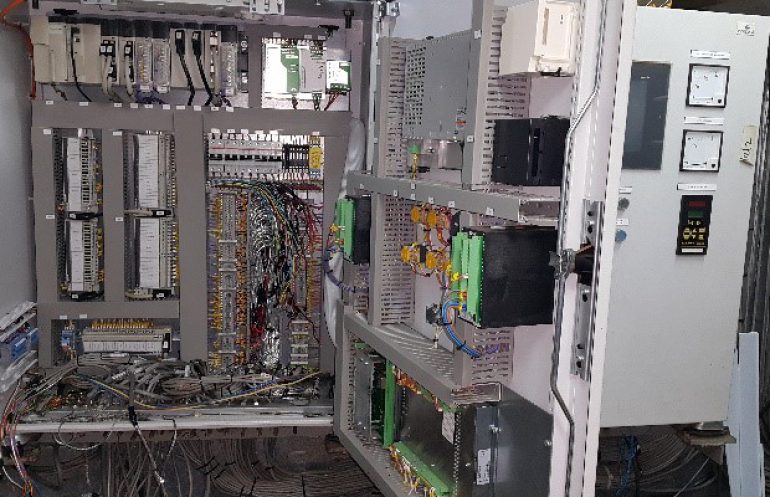

The ZMZ-002577/002579 manipulated skillfully either on the “DCS” or the “FIELDBUS” topology basis (standardized as the IEC_61131 or IEC_61158), depending on the maritime vessel’s demands and level of redundancy as per our reputable client’s requirements.

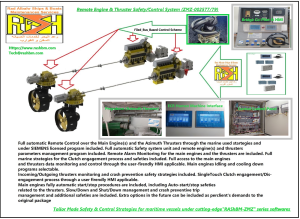

herewith, we’ve upgraded ASD vessel, comprising two sets “Z-Peller” azimuth thrusters (Japanese maker) from 2×180 degree azimuth rotation to the 2×360 degree azimuth full-turn to improve the vessel’s maneuverability.

For the captioned ASD offshore tugboat, we’ve upgraded the safety & remote control system through the original control levers, simultaneously retrofitting visual touch HMI(s) & signal buffers to improve the maneuverability of the vessel.

==> The proposed systems include the several Control Levers and Human Machine Interface (HMI) for monitoring in the parallel mode and will be embedded either on the single separate frame or together with the driver PLC(s), in the control cabinets.

In the hierarchy, the main control/safety PLC(s) are located on the top, the HMI and the control levers, together with their PLC(s) will be assigned as the medium level interface; finally, the lower level equipment in the hierarchy consisting of a wide range of input sensors and outputs.

- Any available marine type output controllers, including the Electro-Hydraulically controlled Regulators/Electronically controlled Pneumatic actuators/ Electronic Servo controllers/ Electronic Regulators/ Electronic Governors/ Electro-Hydraulic Proportional valves and VFD (Variable Frequency Drives) are some examples of compatible actuators to our products.

The actuators are acting as the system’s outputs and the sensors performing the system’s feedbacks through the several designated points.

Imperative and designated alarms assigned to the several points of CPP(s), Engine/Gearbox or Azimuth thruster’s sensors (as the Distributed Control/Fieldbus safeties related to the system) to act as the intelligent and necessary inputs.

RCS-ZMZ-002576-77-79 SYSTEM ARCHITECTURE:

- The system consisting of the two independent sets of the central PLC(s), compose the main RCS stations (as the higher layer in the hierarchy, located both in the ECR and the BRIDGE); Several Sub-Stations connecting to the main stations (as the medium layer, including the Control Levers and HMIs).

- The communication links and data transfer lines establishing through the PROFINET, those will be located in the Wings and the Emergency Stand.

- There are several remote stations consisting of the compact Control Levers and the HMI(s) as the Control and safety monitoring stations (machine control/ interfaces to the operators), locating in the several monitoring stations like BRIDGE, WINGs, ECR, Emergency Stand and etc. (depending on the individual types of maritime vessels and their requirements).

- The interconnections to the exterior monitoring systems and data Networks, like the bridge control station, are achieving through the two sets of independent interface, via PROFINET.

SIEMENS marine approved PLC(s) are playing a vital role in the hierarchy to provide robust platform for the ZMZ-0026xx series strategies to be applied.

The SIEMENS HMI comprising the SSU-ZMZ-002576 engine parameters monitoring through one of the available pages.