==> Our company’s motto: “Innovations for Renovation”.

==>Up to what extent an intelligent marine automation is vital to a marine boiler’s safety?

We’ve been witnessing several casualties & failures through the lack of boiler’s automations & specifically through the water level automation systems.

Supposed, you as an owner of a maritime vessel have owned an obsolete maritime vessel, containing an out of order boiler automations. such a disaster to the engineers & staff, leading to a catastrophic situation, making the engine room watchkeepers to continuously monitor the boiler’s water level & boiler’s steam pressure.

The water level maintain process to a marine boiler is playing an imperative role, as any failure to such a time consuming maintenance (through the staff) shall lead to a catastrophic results like complete vessel overwhelming!

Just, like a malicious act of an anti-virus over any computer, lack of automations over the water level maintaining process to a marine boiler, despite of the disasters to the staff, shall lead in-turn to a long term damage to the smoke or water tubes inside the boiler, due to become continuously exposed to several stresses.

On the other side & as a second priority to makes the vessel fuel-economy, mainly the engines are designed to work on the HFO, instead of diesel oil and maintaining the steam pressure is another process, expecting from an automation system over any marine boiler.

Whist any maritime vessel is sailing, both the above mentioned processes (water & steam Pressure maintaining) are combining together by means of an economizer & auxiliary boiler shall act as an water & steam drum or considering combined boiler types, simultaneous automations over whole process is expected.

BAS-ZMZ-002586

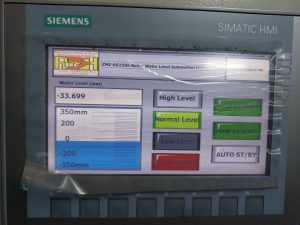

==>Herewith, considering an obsolete automation system in the attended boiler onboard a 33,500 MT (DWT) general cargo vessel, the retrofit project under SIEMENS platform (BAS-ZMZ-002586) has been done.

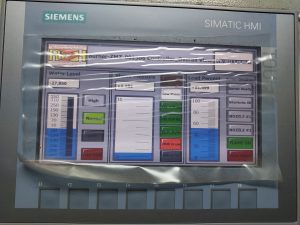

A specific water & steam level automation PLC has been designated to continuously monitor & maintain the level & pressure & communicating on the PROFINET to the burner’s automation PLC.

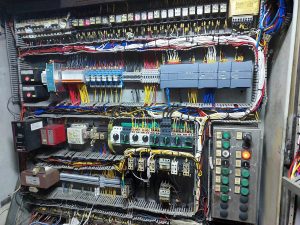

In the captioned project, we’ve retrofitted two set individual automation PLC (s) inside the obsolete control panels (RINA classification society’s approval has been gotten) & a robust & marine approved type PLC are being hired to last against such a harsh environment (adjacent to the boiler) considering minimum 55 centigrade degree of air temperature & unfortunately no any cooling means!

Boiler’s Burner safety & controller retrofitted inside obsolete control panel for AALBORG boiler.