==> What is a marine alarm monitoring system & what are purposes behind installing it in a ship or a maritime vessel???

==> During the past decades, always we’ve been witnessing the marine ship’s automations strategies foot print on the maritime industries are dramatically increasing & consequently personal injuries & faults are vanishing or dwindling in-turn.

==> Also, as the maritime vessel’s owners, have been struggling to maintain the automations to makes it more lucrative, as to save the machineries (safety of the machinery) & save the engineers engagement time to monitor the running conditions of the machineries ( to hire the ship’s automations instead of the watch-keepers).

Such advantages over the safeties & cost benefits, on the other hand definitely brings about an exclusive situation that failure over an enhanced automation like the alarm monitoring system, shall lead to a catastrophic situation, both for machineries & staff.

The oldest models of the marine alarm monitoring systems mainly had been established over the marine approved computers & due to less robustness of such hardware in compare to the PLC(s), we’ve been facing with more failure over them.

==> As a matter of fact, the Programmable Logic Controllers are being designed & fabricated specifically for the control & monitoring purpose & more robustness through them against any harsh environment like marine applications are being measured.

==> Moreover, the opinion through the designed automations over the maritime industries were basis over the keeping one central core as the database to the machineries parameters & that one were constructed on alarm monitoring system; therefore, complete monitoring & safeties were being shared in between the AMS as the central core with other automations like the engines safety systems on the other side (to makes the automations more cost effective).

Consequently, failure over the AMS shall lead to a catastrophic situation.

==> Herewith, I’m on this opinion that to prevent such disasters at sea, it’s more reasonable to enhance the automations over several databases (being stored in the several CPU(s) as the safety cores): construction of the automations shall be established over a network to share data in between each others.

==> Redundancy: To bring about redundancy over the automations, it’s compulsory to save the running condition & prevent from probable failures over the hardware (for instance by making CPU(s) doubled) to avoid losing the control & safety over the machineries.

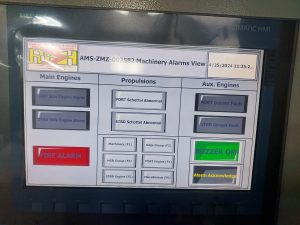

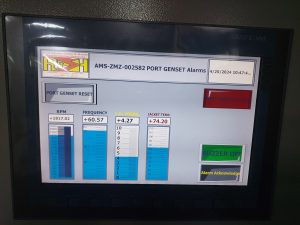

To achieve redundancy over the Vital machineries, we’ve established dual monitoring & simultaneous safety for each & every engines & propulsion controllers individually.

==> Our company’s AMS, consisting of individual PLC(s) for each machineries (working in the background for safety & monitoring), as long as one central monitoring PLC (AMS-UMS).