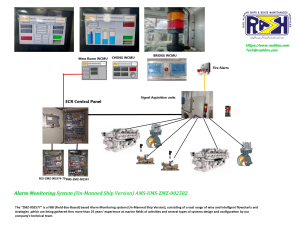

introduction: An Alarm Monitoring System (Un-Manned Maritime Ship) for the marine use is a platform on which whole marine field’s machineries are being controlled and monitored for the pre-defined correct working conditions through a range of the enhanced transmitters all over the processes.

DCS SIEMENS based AMS

As the ordinary monitoring level, the basic model has been providing only the essential monitoring means to provide un-manned maritime ship condition, distributed over the SIEMENS PROFINET all over the maritime vessel’s areas.

condition As an enhanced model, many remote start & stop functions, including the “pumps auto standby” function to ensure the advanced version of the UMS ship automations are applicable through our products.

==> Our product is a robust & reliable successor to any obsolete & out of order monitoring systems & can be implemented onboard maritime vessels to renovate and/or retrofit their safeties.

Our AMS has been integrated basis on the marine-approved PLC (in the hierarchy located on top) as a cutting-edge technology platform from the prominent maker: SIEMENS

Our AMS has been integrated basis on the marine-approved PLC (in the hierarchy located on top) as a cutting-edge technology platform from the prominent maker, SIEMENS, and the relevant strategies are established on the ZMZ-basis software and has been manipulated as below:

- Top Hierarchy (PLC): The “AMS-ZMZ-002582” has been basis on the “FIELDBUS” topology (standardized as the IEC_61158) and comprises the “PROFINET” protocol to communicate to the integrated internal network of the system itself and other parts of an enhanced network, consisting of the control and monitoring systems (For instance the PMS ZMZ-002581 and the RCS/SSU ZMZ-002577/002579).

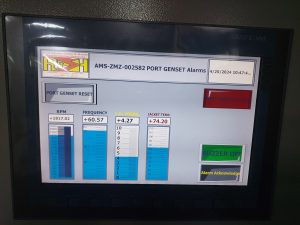

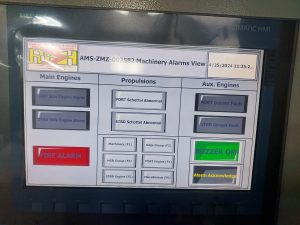

- Human-Machine Interface (HMI):

- Located on the medium level in the hierarchy.

- Displays real-time data and alarm status.

- The HMI displays the alarm information, indicating the nature and location of the issue.

- Allows the ship staff to monitor the machineries, acknowledge alarms, and reset the system.

- The HMI(s) are logging the data and providing the “Alarm Log” and “Alarm History” to the engineers onboard the maritime vessel.

- Field’s Transmitters:

- In the hierarchy located in the lower level and collecting necessary data and acting as the SAU (Signal Acquisition Units).

- These are the input devices that monitor various parameters such as temperature, pressure, tanks level gauging and etc.

- Alarm Devices:

– Online Monitoring (through touch HMI)

– Visual alarms (lights, indicators).

– Audible alarms (sirens, buzzers).

- UMS (Un-Manned Ship):

- Enhanced network consisting of the extra HMI(s) located in the several stations like Bridge, Offices, Duty Mess Room and cabins.

-

-

Advantages of Using PLC in Alarm Monitoring Systems:

-

Reliability:

PLCs are highly reliable and designed for harsh industrial environments. They provide robust performance and are less prone to failure.

-

Flexibility:

PLCs can be easily programmed and reprogrammed to accommodate changes in the monitoring requirements or system upgrades.

-

Scalability:

The system can be scaled up by adding more input/output modules as needed.

-

Integration:

PLCs can integrate with other automation systems on the vessel, such as propulsion control, power management, and safety systems.

-

Real-time Processing:

PLCs offer real-time processing capabilities, ensuring immediate detection and response to abnormal conditions.

-

Maintenance-free system as applicable.

User-Friendly pages are applicable to the AMS’s HMI to provide conditional monitoring to the machineries.