Offshore Vessels and barges

Our company’s services includes renovation & upgrade obsolete maritime offshore vessels to improve their safety & maneuverability:

==> One of the recent targeted vessels renovated using the RCS-ZMZ-002576-79 under SIEMENS marine approved platform:

An ASD marine Push-Tug comprising of: two sets of the marine Niigata engines (2x 6L25HX, 2x1343KW) & two sets of the marine thrusters (Z-Peller hydraulic) & observing obsolete safety & control systems over the steering system ( hydraulic azimuth system from SUMITOMO & MOOG controller – J062 series) & marine gerabox from NICO under-licensed from Twin-Disk (USA) & Smooth-Clutch controller ( Slipping-Clutch) through the # Pneumatic E/P controller (through the changeover valves common in between the Clutch & Governor) is being renovated & retrofitted by means of the versatile & hassle-free ZMZ series safety & controller system.

Main challenges over the steering controller were:

1-The obsolete servo-valve (Moog j062 series) over the Sumitomo hydraulic pump (Moog j062 containing the Mechanical Feedback), which is now being triggered through the Moog amplifier-card, comprising the two sets of the intelligent closed-loop control systems, which are being controlled through the PLC (which are forming the two individual closed loop feedback signals) & are being monitored through the azimuth-angle feedback and the MFB of the valve (mechanical-feedback embedded in the servo-valve) those are being hired and processed in the subroutine software.

2-The second challenge was more determinative and aimed to upgrade the 180 degree rotation of the azimuth thrusters (original Japanese model) and brought about an improved maneuvering strategies to let the 360degree azimuth-rotation over the thrusters, which is successfully manipulated through the intelligent software embedded in the ZMZ-002576-79 strategies and fantastically improved the maritime vessel’s maneuvering abilities in the several angles.

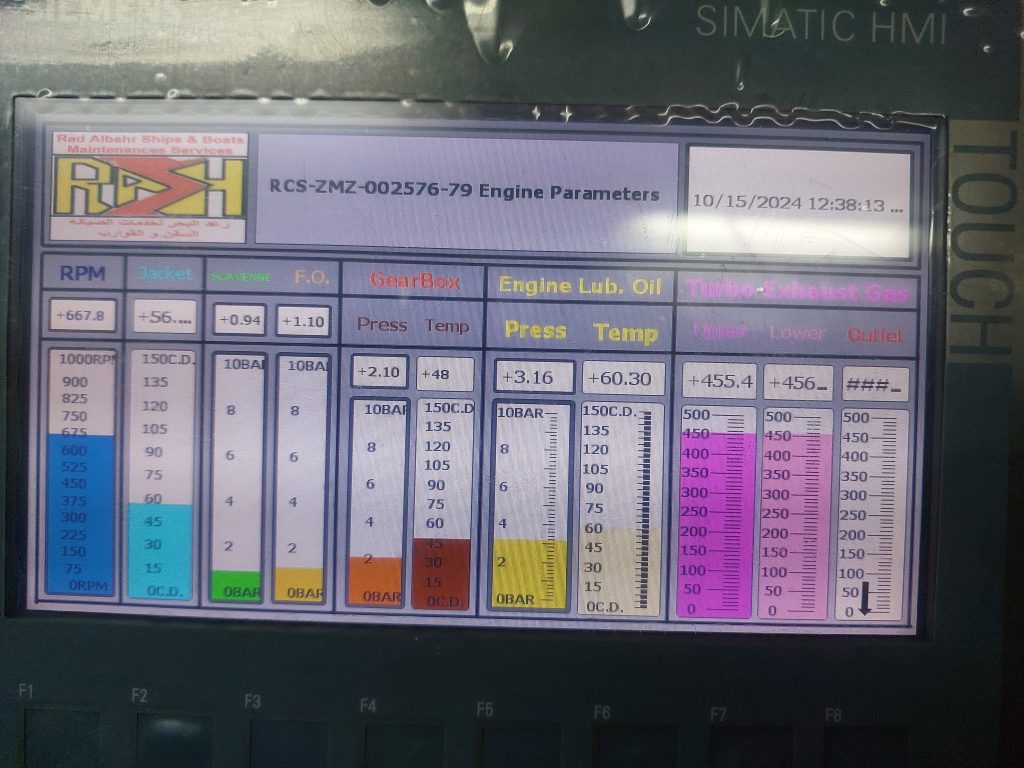

Full safeties over the gearbox & slipping-clutch (an option to the Japanese made gearbox to enable the Omega-Control functionality) is being established and brought into service.

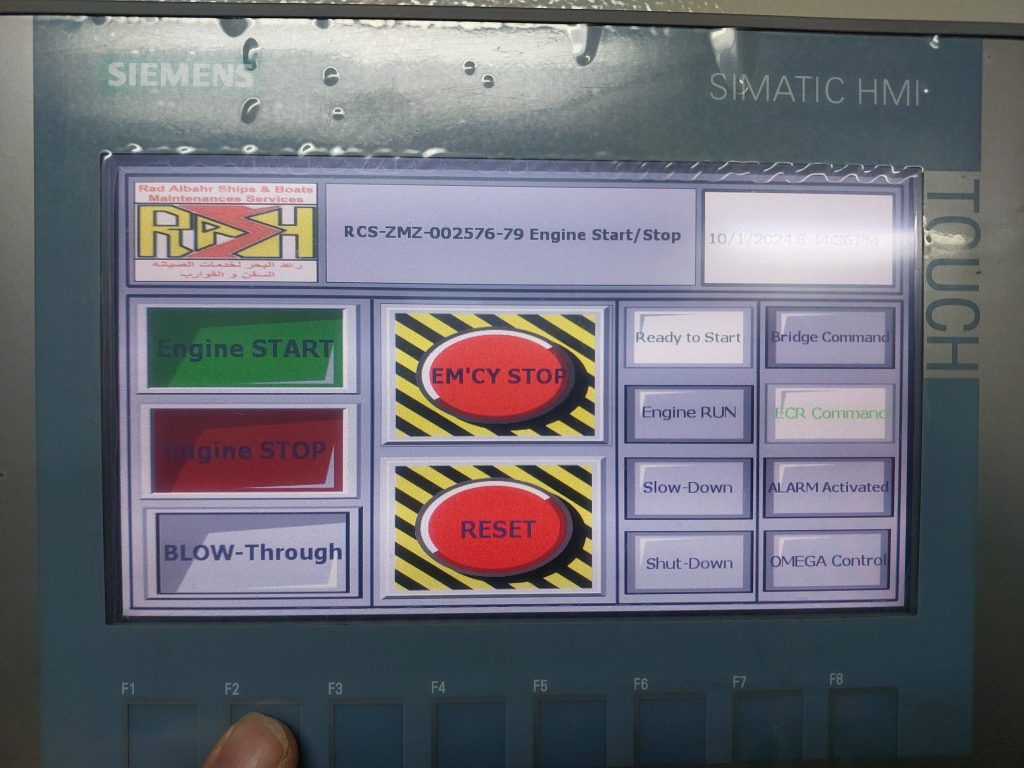

Full safeties & controls over the engines, including the remote start, stop & Blow-Through functions established, via the user-friendly HMI touch screen.

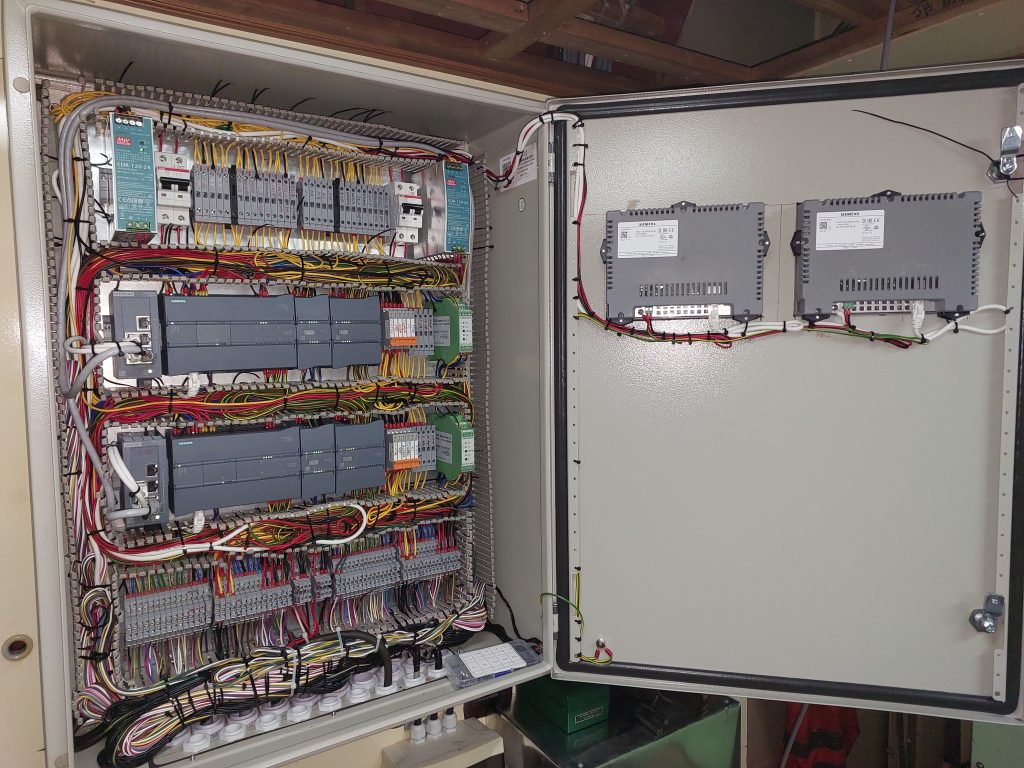

A cutting-edge technology through the SIEMENS marine-approved PLC (SIEMENS 1217C), observing the ZMZ series software is being embedded to the safety & control systems to bring about a hassle-free 360 degree azimuth operation through the maritime vessel.

Speed monitoring over the engines are being established through the KOYO encoder, to be provided for the marine-SSU to precisely monitor the RPM.

Final sea-trial has been carried-out & maritime-vessel is being delivered to the owner.