اطلاعات پروژه

- دسته بندی: Products

- REMOTE ENGINE/GEARBOX/THRUSTER/CPP CONTROL & SAFETY SYSTEM (ZMZ-002577/002579) :

جزئیات پروژه

INTRODUCTION: The ZMZ-002577/002579 manipulated skillfully either on the “DCS” or the “FIELDBUS” topology basis (standardized as the IEC_61131 or IEC_61158), depending on the maritime vessel’s demands and level of redundancy as per our reputable client’s requirements. The proposed systems include the several Control Levers and Human Machine Interface (HMI) for monitoring in the […]

ادامه جزئیات پروژه

INTRODUCTION:

The ZMZ-002577/002579 manipulated skillfully either on the “DCS” or the “FIELDBUS” topology basis (standardized as the IEC_61131 or IEC_61158), depending on the maritime vessel’s demands and level of redundancy as per our reputable client’s requirements.

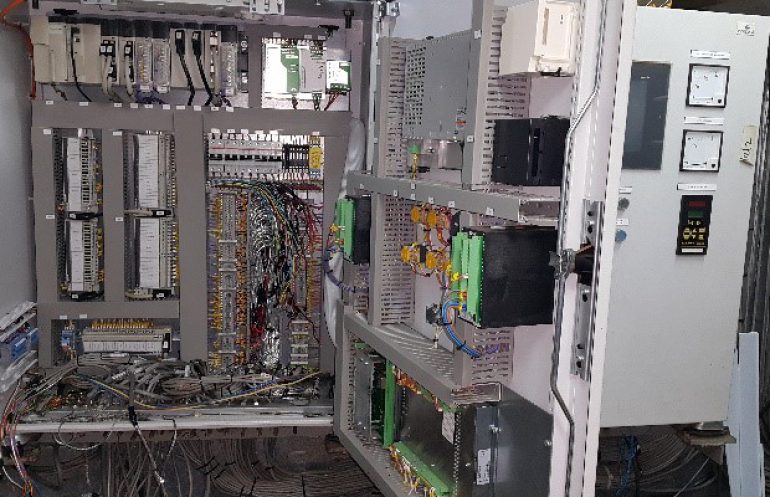

The proposed systems include the several Control Levers and Human Machine Interface (HMI) for monitoring in the parallel mode and will be embedded either on the single separate frame or together with the driver PLC(s), in the control cabinets.

In the hierarchy, the main control/safety PLC(s) are located on the top, the HMI and the control levers, together with their PLC(s) will be assigned as the medium level interface; finally, the lower level equipment in the hierarchy consisting of a wide range of input sensors and outputs.

Any available marine type output controllers, including the Electro-Hydraulically controlled Regulators/Electronically controlled actuators/Electronic Servo controllers/ Electronic Regulators/Electronic Governors/Electro-Hydraulic Proportional valves and VFD (Variable Frequency Drives) are some examples of compatible actuators to our products.

The actuators are acting as the system’s outputs and the sensors performing the system’s feedbacks through the several designated points.

Imperative and designated alarms assigned to the several points of CPP(s), Engine/Gearbox or Azimuth thruster’s sensors (as the Distributed Control/Fieldbus safeties related to the system) to act as the intelligent and necessary inputs.

SYSTEM ARCHITECTURE:

The system consisting of the two independent sets of the central PLC(s), compose the main RCS stations (as the higher layer in the hierarchy, located both in the ECR and the BRIDGE); Several Sub-Stations connecting to the main stations (as the medium layer, including the Control Levers and HMIs).

The communication links and data transfer lines establishing through the PROFIBUS DP or PROFINET, those will be located in the Wings and the Emergency Stand.

There are several remote stations consisting of the compact Control Levers and the HMI(s) as the Control and safety monitoring stations (machine control/ interfaces to the operators), locating in the several monitoring stations like BRIDGE, WINGs, ECR, Emergency Stand and etc. (depending on the individual types of maritime vessels and their requirements).

The interconnections to the exterior monitoring systems and data Networks, like Power Management System (PMS ZMZ-002581) and the Integrated Alarm Monitoring System (IAMS ZMZ-002582) achieving through the two sets of independent interface, via PROFINET.

REDUNDANCY:

To ensure the redundancy to the ZMZ-002577/002579, we have established two separate sets of CPU(s) for each station, working independently. The interconnections between the two independent CPU(s), establish via the “PROFINET” CAN_BUS to exchange imperative data in between the two sets of main CPU(s) in each station. For more safety reasons, all stations connecting each other through the parallel communication lines, those are achieving through the separate CANBUS(s).

SEA TRIAL:

Several versions of the “ZMZ-002577” and “ZMZ-002579” have been released, installed and commissioned for our reputable clients. Several maritime obsolete pneumatic control systems have been retrofitted through our compatible intelligent control system to upgrade and renovate the maritime vessels.